Engineering Expertise

Our engineering expertise at RAO goes well beyond just deep drawing. To support our wide customer base & product needs, we are also highly proficient in:

metal fabricating (laser, brake forming)

metal fabricating (laser, brake forming)

stage & progressive stamping

welding

sub-assembly

Custom tooling, when required for your project, is designed by our engineers & built in house by our toolmakers. At RAO, we control all aspects of design & build of your tooling – a key to our success. We have a well-equipped tooling department, with over 13 skilled toolmakers across our 3 shifts to help us deliver your projects right & on-time, the first time.

Prototyping services are also available. Our wide range of forming, cutting, and welding capabilities enable RAO to help get you to that next step in your design.

RAO has equipment, knowledge, and skill to support your needs: from concept design to production delivery. We encourage you to contact our engineering team to discuss your next project. Our engineers will help you find the lowest cost, best possible design to meet your applications.

Engineering & Development Team Support

Pro/E design software

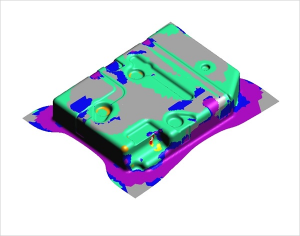

Autoform Forming Simulation Software

- Finite elements analysis; “Virtual press tryout”

CAM Software

- Surfcam & Fanuc wire

PC/DMIS quality control software

Equipment Highlights

Tooling Department

- CNC 3-axis machining, up to 90” x 130” tables

- CNC wire EDM cutting

- Turning to 36” diameter

Production

- 40+ Presses up to 850 tons & 98” x 51” beds

- TIG & MIG welding; steel, aluminum, stainless steel

- Spot welding

- Fastener insertion

- Laser cutting

- Press brake forming & folding

- Aqueous washing